UV 1164

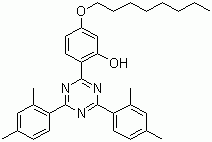

Chemical Name: 2-(4, 6-Bis-(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-(octyloxy)-phenol

Commercial Name: UV 1164; UV 1164

CAS NO.: 2725-22-6

EC Number: 412-440-4

Molecular Formula: C33H39N3O2

Molecular Weight: 509.68

Molecular Structure:

Characteristic:

Property | Standard |

Toluene insoluble | ≤ 0.5% |

Specific gravity @ 20 °C (g/cm3) | 1.15 |

TGA 10 mg @ 10 °C/min under | Mass Loss |

347 °C | 1 % |

365 °C | 2 % |

Solubility @ 20 °C | g/100g solvent |

Butanol | 3 |

Butylacetate | 17 |

Methyl ethyl ketone | 17 |

Xylene | 25 |

Specification:

Items | Standard |

Appearance: | White or light yellow powder |

Purity(HPLC): | ≥98.5% |

Melting point: | 88~91℃ |

Moisture: | ≤0.3% |

Absorbance (10% Toluene, 440nm): | ≤0.3% |

Ash: | ≤0.1% |

Description:

UV 1164 is one of the most powerful and durable UV absorbers, it derives from a hydroxyphenyl-S-triazine. Its absorbance ability is higher in the B region of UV radiation where the absorbance goes from 290 to 350 nm, with maximum absorbance at 342 nm. This is the wavelength where the most of ethylene polymers start to decompose.

The benefits of UV 1164 are: high light stability, minimum contribution to the final colour, the low interaction with metallic ions (like catalysis residues) and very low volatility that limits processing problems like plate out, surface imperfections and die lip building for the entire service life.

UV 1164 is the UV absorber of choice for greenhouses PE films used in very sunny areas. Moreover, UV 1164 is the most used UV absorber to increase the light fastness of many organic pigments and dyes, in the synthetic fibres (PP, PA, PET) mass dyeing.

Application:

Thanks to its UV-B absorption and its low volatility and the tendency to sublimate, UV 1164 is highly recommended to be used in engineering resins like PA, PC, PET, PBT, PMMA, POM, PE, PP, TPO, ASA, ABS and polymer blends and in general in all applications that require a wide surface area like fibres, laminating films, PE/EVA films for the greenhouses that must resist for 36-48 month of intensive exposition in very sunny areas, and for PC roof sheeting.

UV 1164 is also a UV absorber of choice for powder coating (for the automotive and for coils) cured at high temperature over 185 °C and exposed to environmental attack.

In the other freilds, UV 1164 also cold be suitable for PU, Poly Keton.

Dosage:

UV 1164 needs to be added in a percentage from 0.15% to 5% (on finished product considering pigments and other additives).

Storage and transportation:

The chemical stability is good. It can be stored and transported according to the general chemical matter regulation.

Packing:

20kg per drum or as requirement.